A New Era of Nouveaux ‘Nobles’?

We are currently witnessing the emergence of a new era that is already changing our world forever. Luxury houses are constantly in search of meaningful, ethical and sustainable solutions to petrochemically-derived materials that may end up in wastefills. Do bio-based alternatives to fossil fuel disaster offer the prospect of a real way forward? Still in its infancy, the concept of bio-engineered fabrics may offer the most planet-friendly and noble alternative to the luxury industry. To which extent could lab-based solutions be embraced by the luxury sector? Will they ever be accepted as ‘noble materials’?

The French, in the seventeenth century, produced furniture with new exotic ‘noble’ materials -tropical wood, marble, gilding, marquestry, tortoiseshell, and bronzes. In the eighteenth century it became possible to replace these rare materials with less luxurious substitutes, and indeed to use these in innovative ways for new decorative effect. The new materials included lightweight cottons instead of silk, earthenwares instead of porcelain…ormolu and cut steel instead of gold and silver, varnishes and veneers instead of exotic woods. The arts of imitation were combined with the science of invention. Manipulating these new materials was an act of invention itself.” (1)

Much of the Industrial Revolution was about new materials that gave rise to the “manufacture of new alternative consumer goods which sometimes copied, but more significantly ‘imitated’, the spirit of global luxury” (2) “Such new products were also technological achievements. Made with new materials, fabricated with novel production methods deploying the division of labour and all manner of hand, horse, water-powered, and eventually steam-powered machinery, they were the success story of an industrial revolution. At that time, the world was witnessing “the invention, making, and buying of new, semi-luxury and fashionable consumer goods – teaware and dinner services, glassware, japanned tea tables, boxes, cabinets, and trays, plated tea urns, coffee pots, brass and silver candelabra, cutlery …buckles, buttons … and carpets. Only 261 years since the advent of that Revolution, we find ourselves living in a polluted planet!

The Digital revolution that began in the 20th Century has now brought us into computer-assisted creation, connected fibers and even the use of textile as a new connected device to enable traceability and even cryptology methods that are complicated to copy, and thereby bringing a new added-value to fashion and luxury brands, but are such fabrics environmentally-friendly or noble? Alongside such technofabric trends has been a much greater shift towards recycling, upcycling, circularity, waste becoming a resource, and vegan textiles competing with animal-derived materials. Can waste-derived products or vegan synthetics ever be considered as ‘noble’ enough for the luxury sector?

Current linear manufacturing and consumption practices of industrial materials, especially fibers and textiles, are not sustainable. The potential of biofabrication to engineer a range of materials, coupled with the enormous environmental impact of conventional textile manufacturing, has propelled research into more sustainable, bio-based textiles. Nowadays, a host of bioengineering strategies can be implemented to transition from the current linear paradigm to more circular, biocompatible processes. These approaches span from the nanoscale to the macroscale for the sustainable production of textile fibers with broad application across sectors, including fashion, biomedical, and industrial applications, with potential to accelerate a paradigm shift to a circular materials economy. (3)

Some of the main environmental concerns associated with bio-based fibres include their environmental impacts, water and land use, feedstock competition, agricultural intensity, recyclability and microfibre release. These aspects, along with others, need further consideration and require both a systemic and a tailored approach to better understand the merits and drawbacks of bio-based textiles before bolder upscaling actions are undertaken. (4)

The higher the luxury, the more detailed the story. As such, the process of creating and crafting tends to add rational value to the final product / creation whilst the sensorial aspects and meaning attributed to the final creation tends to enhance the emotional value of the final creation. Within the details of the masterpiece and the mastery of the craft, we expect to find craft traditions deeply rooted in their history, beliefs, and values, passion, and innovations in every step of the process. It is here where the ‘noble material’ story comes into play. Luxury is expected, in indeed demands and even requires the use of the finest materials known to man, and ideally, the rarest. Hence the disdain for petro-chemical-derived imitation fabrics – including certain so-called ‘vegan’ materials – that cannot qualify as ‘noble materials’. Do bio-fabrics offer the way forward?

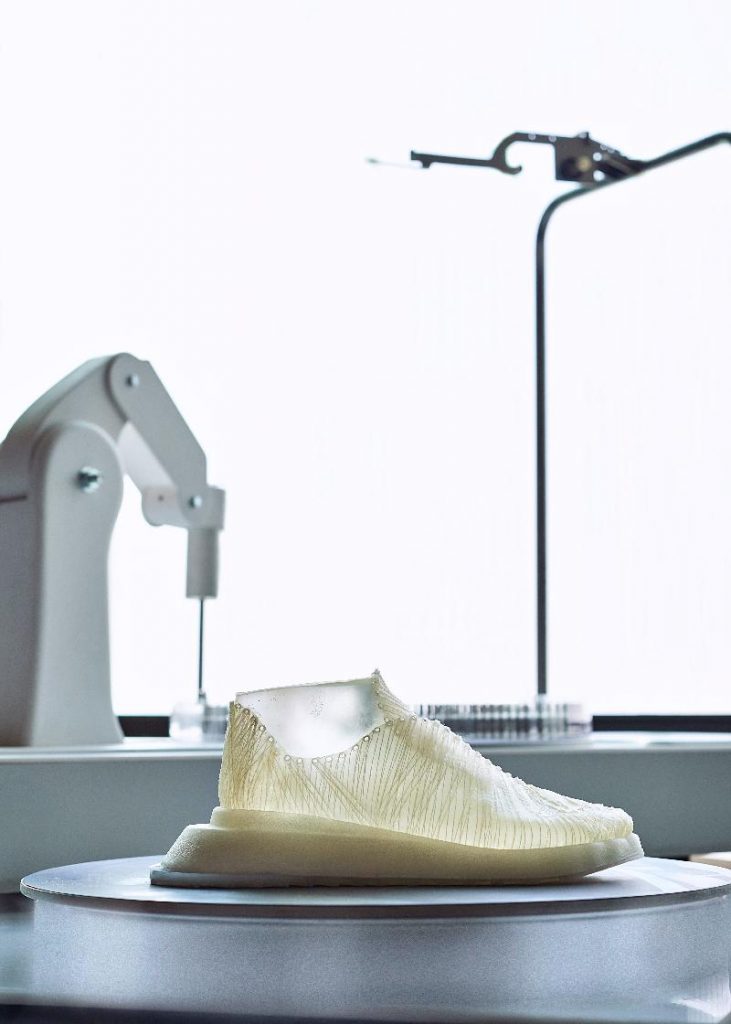

@BIOFABRICATE Design Lab at the @BIOFABRICATE Paris Summit 2024. Copyright @BIOFABRICATE™; Photo Credit: Robert Leslie

Are Vegan Materials Noble?

“Many fashion companies, especially established non-vegan brands, don’t fully understand what does and doesn’t make a product vegan” says vegan marketer, Sandra Nomoto.(5) “Even if you choose non-animal leather, the process that some products goes through, especially if synthetic, can still include animal derivatives in its manufacturing process. Research shows that leather produced from a cow’s skin is nearly three times as harmful to the environment as vegan leather. That’s why we’re now seeing some amazing innovations in material sciences,” she adds.

“We’ve got wool made from organic cotton, silk from bamboo and even leather made from cactus. Cactus leather doesn’t require large-scale water irrigation, is organic and produces a luxurious and long-lasting material. You can also buy plant-leather made from apples, corn and even pineapples, which isn’t just ethical – it’s just downright cool – who wouldn’t want a bag made from pineapple leather? And it’s this consumer demand for something new that is another big driver behind the rise of vegan fashion,” Nomoto concludes. Stella McCartney has built her brand on vegan principles but what makes her brand qualify as “luxury”? Are any of her materials noble and are vegan-leather alternatives actually better for our environment than the real thing? Vegan leather can be made from plastics which take years to biodegrade, so it’s actually worse for the planet than regular. Micro-plastic pollution is a big threat, as it uses an extensive amount of water, energy and chemicals to be processed and made into the material which sadly impacts the earth. “People think it’s better because it says vegan on it, but that’s because people aren’t taking the time to really learn about what they’re buying,” say Harpers Bazaar UK. (6)

“Leather products treated with natural vegetable tannins are biodegradable and can be easily discarded at the end of their natural life,” explains Maj-La Pizzelli, creative director at sustainable accessorise label, ATP Atelier. “Our collections are made from vegetable-tanned Tuscan vachetta leather. For us, this is a conscious choice on so many levels”.

“Leather is often a by-product from the meat production, which is why many people legalise it more,” Catherine Saks of Danish brand Saks Potts explains. “Danish mink are completely zero waste, the fat is used for fuel on Danish busses, the bones are used as feed to other animals and a large amount are used as fertiliser for organic Danish vegetable production.”

The Interline Sustainability Report 2023 confirmed that “when it comes to the fashion industry’s net negative impact on the environment, materials are major culprits. Across categories, the most ubiquitous are cotton, wool, leather, rayon, spandex, nylon, acrylic, and polyester – the latter four synthetic fabrics being non-biodegradable. Synthetics also now make up 60% of the world’s clothing, (many of them being classified as ‘vegan’) a position they’ve earned through their ability to be cheaply mass-produced, leading to their low prices for consumers, and for being durable, easy to maintain, stretchy, and absorbent – making them key parts of material mixes in a range of different performance applications. But aside from their incredibly long decomposition lifetime, synthetic fabrics leave their own footprint in other places: each time synthetic fabrics go into our washing machines, and during pre-consumer treatment, they shed plastic fibres (or microplastics) that eventually end up in the ocean, where they are being measured as having a toxic effect on marine life.” (7)

Also, they are not all considered as sustainable. For instance, cotton, organic or not. In 1999 The United Nations historically declared that the Aral Sea, once the fourth largest lake in the world, had shrunk to half its former size – a result of unsustainable cotton cultivation that began less than 40 years beforehand. Called “the most staggering disaster of the twentieth century” by the United Nations Development Programme (UNDP), “the 3.5 million people who live in the region have seen their health, jobs and living conditions literally go down the drain. The once thriving fishing and canning industry has evaporated, replaced by anemia, high infant and maternal mortality, and debilitating respiratory and intestinal ailments.”(8)

Similarly, the production of leather is harmful not only for animals, the environment, but also the people who produce it. Turning animal skin into leather requires extensive amounts of water, energy, and dangerous chemicals – including formaldehyde, coal-tar derivatives, and various dyes, some of which contain cyanide. And while there is a fair argument to be had about whether leather is “sustainable” from the point of view of its being a by-product of the dairy and meat industries, the reality remains that the chemicals used during the tanning and post-tanning treatment processes also leave many of today’s leather products unable to naturally decompose, which adds an extra layer of complexity on top of the already-divisive drive to use leather simply because hides already exist as a source of material.

The main argument for vegan materials to be considered noble is that no animal has died for the leather to be produced yet the main reason why animal materials are considered noble is exactly because the beast is considered to have died in the service of a noble cause.

Who defined Noble Materials?

The Oxford dictionary defines nobility as “nobleness of character, mind, birth, or rank” and defines noble metals (e.g. gold, silver or platinum) that resists chemical action, does not corrode or tarnish in air or water, and is not easily attacked by acids. It offers no definition for the broader term ‘noble materials’. In contrast, the French Dictionary, LeRobert, offers the following: “That which is considered superior. Noble, natural (not synthetic) and appreciated materials: stone, wood, etc. Noble metals (silver, gold, platinum).” As such, one must assume that the term could only have emerged after the industrial revolution. Before that event, everything had been created with natural and sustainable materials / ingredients and were simply ‘born noble’.

However, what is noble today may not necessarily be considered as noble tomorrow. In fact, it may even become distasteful, unethical, forbidden or illegal. Rhino horn and Tortoise shell are just some of the ‘materials’ that are no longer legal and thereby should no longer considered noble. In 1973, the trade of tortoiseshell worldwide was banned under CITES (the Convention on International Trade in Endangered Species).

Only one high luxury house in the world continues to legally use tortoise shell and do not seem to have been accused of being unethical. We speak of the prestigious bespoke eyewear specialists, Maison Bonnet: Lunetier based in Palais Royale, Paris and Mayfair, London. This forth-generation house of master craftspeople is the world’s ‘haute couture’ of eyewear. It chooses to work with three materials: Acetate – organic resin is mainly composed of cotton flower and wooden beads; Buffalo horn originating from India, Vietnam, or Madagascar ; and the the historical material of the house- rare tortoise shell (originated from the hawksbill turtle –“the most noble of all materials”(9). Legend has it that they bought all the world’s tortoise shell stocks just before the Washington Convention banned the material. Only the Akatsuka Tortoiseshell Corporation in Japan remains a direct competitor.

[ What is the Washington Convention? ]

The Washington Convention is an agreement intended to protect endangered species of wild fauna and flora by regulating international trade in the wildlife. (182countries and regions and EU are contracting parties to the Convention, as of April 2018)

Chanel along with other luxury houses no longer us ‘exotic skins’ meaning from animals that are not normally eaten. ‘By-products’ from animals that are slaughtered for meat consumption are considering as economically beneficial to simply turning hides to landfill. As such, these hides may be referred to as cruelty-free leathers and noble materials. Let us not forget that most silk is not derived in a ‘cruelty-free’ manner other than India’s Ahimsa or ‘Peace Silk’.

The World Organisation for Animal Health (WOAH) recognises the production of animals for animal-based materials, such as leather and fibre, as a legitimate practice, however, it carries an associated ethical responsibility to ensure that acceptable animal welfare outcomes are achieved. « To fulfil this responsibility, Hermès focuses on animal welfare, not only as an important entity in its own right, but also as part of an integrated vision of an ethical, social and environmental sustainable farming systems. This ‘One Welfare’ approach, which considers the important interconnections between animals, people, and the environment, is at the core of our animal welfare strategy, » the house confirms.

The animals covered by the Hermès Animal Welfare Policy « include crocodilians, ostriches, lizards (where leather is a co-product), and cattle, calves, goats, sheep, deer, and pigs (where the leather is a byproduct). When leather is a co-product, it represents a significant proportion of the total value of the products from the animal. In this situation, Hermès has a greater ability to influence the policies and practices relating to animal welfare within the supply chain. When leather is a by-product, meaning that the relative value of the hide is small compared with the other animal products (for example, meat), Hermès has less influence on policy and practices. In this context, we remain fully committed to working with other animal industries to initiate the changes required. Hermès also sources fibres (wool and hair) from camelids, sheep, goats, and horses; down from ducks and geese; and horn from buffalo. These animals are also included in the Animal Welfare Policy », it states.(10)

Will Upcycled Waste ever be considered as Noble?

Waste is fast being recognized as a resource. Circular economy objectives have become a norm but are there any waste-derived products that are considered to be noble? For recycled gold from discarded electronics, there is no debate however, although recycling waste is a noble cause, much transformed waste is not of a quality high enough to be used by the luxury houses as is often the case for many so-called ‘vegan’ materials that may even include polyvinyl chloride (PVC), polyurethane and textile-polymer composite microfibres that are known to be unsustainable and even harmful.

“Pre-consumer, or commercial textile waste, are fabrics or materials that are discarded during the process of manufacturing goods by companies throughout the supply chain. Because this is an industry practice, most people are completely unaware of how severe the issue is, or that it is even happening behind the scenes. It’s estimated that each year, 53 million tons of textiles are used to create clothing and 12%, or 6.3 million tons, are wasted during design and production. What’s worse is that 62% of fabric is synthetic or chemical. These fibers take 30-40 years to break down in landfill, and 100 years to fully decompose, if ever”. (11)

Unfortunately “circularity” is now one of those trending sustainability terms that everyone is talking about, but in reality, no one really seems to know how to implement. The definition is fairly straightforward: use as many of the outputs of one cycle of design, development, and sale, as possible to become the inputs for the next cycle, and so on. Puttng that into practice involves challenging established practices at every stage of that cycle. And the danger of “circularity” falling into a greenwashing trap, and losing its concrete definition, is that we desperately need circular systems in order to turn things around for the better. Realistically, there are no other alternatives to reducing waste, and a circular approach starts with those simple questions that force us to stop and think about our actions. “Why is this waste?” (12)

In Paris there is a young dynamic start-up run by bio-engineers called Les Matériaux Parisiens that offers to collect, source, dry, grind and mix and produce unique materials and products for companies that create waste and wish for circularity. They collaborate with leading designers, creators and artists to produce unique new products that can be used in different industries, ideally the very demanding luxury industries that define the standards of quality. One would imagine that companies are lining up to offer their waste but it is not the case. Waste suppliers are few and far between. The innovations that they have developed so far are 100% made from waste with no exogen resin or petrol based binders. (13)

Products include a chess board, face sculptures and lamps created with NaturiO – a biowaste made from coffee grounds, wood powder ; Mineral based white plates and sculptures and paper based pen holders. The idea is that a company’s waste is used to produce their own little luxury objects for corporate gifting and the like. They share an old tyre factory that has been converted into a multi-atelier space, known as Ateliers Diderot hosts many ‘circular economy’ start-ups half-way between the famous Les Ateliers Hermès Pantin and the Chanel-owned multi-ateliers (Maisons d’art) space known as le19M housing nearly 700 artisans and other experts. The fact is that some waste-derived materials may never be accepted as ‘noble’ by either the luxury houses or their clients.

Prinicipal Sponsor Kering at the @BIOFABRICATE Paris Summit 2024; Copyright: @BIOFABRICATE™. Photo Credit: @Robert Leslie.

The Case for Biofabricated Materials

Biofabrics are often hyped as the future of sustainable textiles but are they ‘noble’? Will biofabricated materials become the new ‘nobility’?

Biofabricated textiles are not considered as synthetic because they are living naturals born in the lab, grown from live microorganisms, such as bacteria, yeast, algae and fungi root structures. “Through a process of bioengineering, these microorganisms can be designed to produce biopolymers which can be extruded using a spinneret to create yarn, or grown in a mould, to create a material that can be harvested with zero waste”. (14)

In January 2024, Paris hosted the very exclusive BioFabricate Summit “where design meets biology”- for “innovators, brands and investors leading the transition to a biomade future”.

The event -with the Kering Group, owners of Gucci, St Laurent, Balenciaga and Boucheron, as principal sponsor – aimed to be a deep dive showcasing the next wave of bio-innovators and learning from the more established players. New strange and original bio-engineered or lab-grown materials designed for the luxury, fashion, sport and beauty industry were on show, all looking for finance and an opportunity to launch in high luxury and then “scale”.

While there is a significant amount of time, money, and effort being poured into identifying and commercialising new alternatives to traditional materials that can sidestep some of their more problematic elements, large-scale use and industrialisation are still far from commonplace, and the chance is that it may still be a while until we see sourcing processes shift their emphasis to these alternatives. (15)

For instance, Bolt Threads (the lab that created mycelium-based, leather alternative Mylo used by Hermès, Stella McCartney, Kering and Adidas) was closest to wider commercialisation but recently ceased production because of funding issues. Developed by California material innovation startup Bolt Threads and launched in 2018, the bio-based material had been widely lauded as a more sustainable alternative to conventional animal leather. Bolt Threads CEO Dan Widmaier says Mylo was “devastatingly close” to commercial scale, but inflation and waning funding opportunities have brought the company to a standstill. “We are not immune to the same macroeconomic pressures everyone else is facing, so we have paused Mylo to reassess what works and what will work in the future,” Widmaier told Vogue Business. It’s not out of the question that Bolt Threads would sell the technology in the hopes of getting Mylo to market. “There’s no finality to this story yet. Humanity needs a more sustainable future or we will cook ourselves on this planet with climate change, and fashion has a huge role in that. My hope is that we solve this problem for the good of everyone on the planet — that’s why all options are on the table.”(16)

Over the past few years, much of the fashion industry’s funding has been funnelled to companies that have something to do with AI, 3D or digital product creation (DPC)) – something those working on the frontier of developing new materials are acutely aware of. There has been, then, more interest in digitising existing materials to improve the efficiency and transparency of supply chains that incorporate them, than there has been in pursuing genuinely novel new materials. But even in spite of the odds being stacked against alternative materials, the industry as a whole does appear to be making progress – albeit in isolated islands. But how far have they really been able to advance? How viable it is to scale new materials in today’s fashion market? And what more needs to be done by brands, manufacturers, and consumers to help potentially revolutionary new fibre, process, and material ideas to take flight? Any new material is expected to be flexible and built for longevity.(17)

“The barrier to entry for new materials in fashion is incredibly high. New innovations can seem compelling in academia, where the abstract use case is strong and the experimental results bear it out, but actual customers have incredibly high demands for any new material – and innovations, as we know, tend to be price- prohibitive” wrote The Interline News & Features Editor, Emma Feldner-Busztin (18) “What’s more, in the state that fashion currently is in, many brands and manufacturers aren’t willing – or able, for that matter – to take risks to purchase or produce differently. And often, the same brands are not expecting the consumer to act differently either, or to be willing to part with additional money in order to substantiate the investment needed on the brand’s part to spearhead the bringing of new materials to market », she adds.

There are some game-changers working in the space – people who recognise that obsessing over the finer details of commercialising new fabrics is failing to see the forest for the trees, and that the pursuit of real change lies in the radical overhauling of not just fabric use, but the entire value chain. One of these is an intrepid biotechnology company that has already been truly and positively disruptive: SQIM

1. SQIM, formerly known as MOGU SRL, successfully closed a €11 Million funding round at the BioFabricate Summit in Paris. The funding round, led by CDP Venture Capital with participation from ECBF VC, Kering Ventures, and Progress Tech Transfer, will enable SQIM “power up its two business lines and brands – EPHEA™️ and MOGU™️” and expand Industrial Scale-Up through the launch of a newly dedicated Demo Plant, while further accelerating Research and Development activities, and Strengthening the Team. (19)

Established in 2015, and globally recognized as pioneer in mycelium-based technologies, SQIM is a multidisciplinary, innovation-driven biotech and biomaterials company at the forefront of material innovation. It delivers innovative materials and products by harnessing the natural power of fungal mycelia, and today primarily addresses the Fashion, Interior Design, and Automotive markets. SQIM was recently honored with the prestigious Andam Fashion Awards (Innovation Prize) for its unprecedented class of biofabricated materials – ephea™.

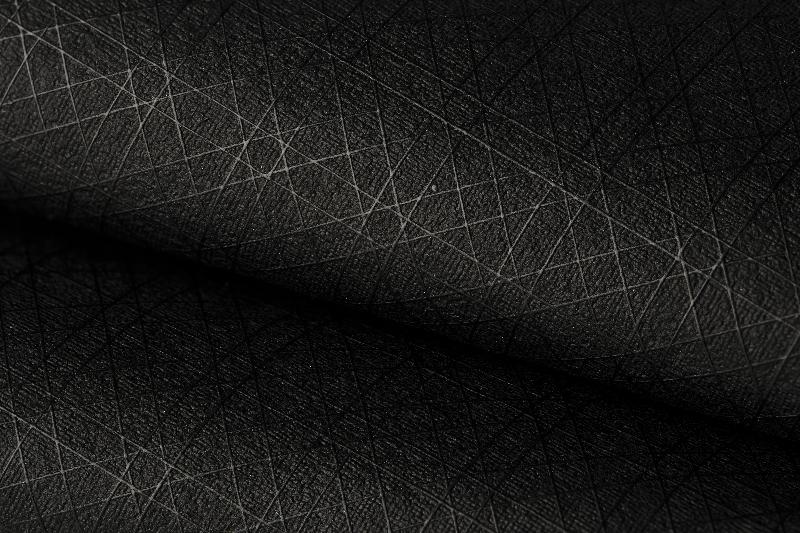

EPHEA™ is a cutting-edge, mycelium-based material exclusively developed for Balenciaga -the first of its kind- is an organic, viable alternative to leather that is finished with a sustainable treatment. Engineered to diminish an ecological footprint without compromising quality or technical performance, it is made from the vegetative body of mushrooms. Specifically, it is woven from an abundant, quickly growing organism that uses minimal resources and emits trace amounts of CO2 as it feeds on low-value agro-industrial residue. Bio-fabricated using SQIM’s proprietary process, EPHEA™ was used in the Balenciaga Winter 22 collection for a floor-length coat. (20)

“In March, Balenciaga sent a black, hooded wrap coat down the runway during its Autumn/Winter 2022 show, set against a swirling, snowy backdrop”, Vogue UK reported. “Made from bio-based material Ephea and on sale for €9,000 starting today, the coat marks the luxury brand’s first release using a leather alternative made from mycelium, and is the first commercially available garment to be made using Ephea”.(21)

“Balenciaga’s new coat proves that real leather is dead,” https://hypebae.com/ reported. (22) “We’ve seen it before with Stella McCartney’s Frayme Mylo bag, released earlier this year but Balenciaga’s coat offers a higher level of craftsmanship in terms of its volume and thickness. The garment is made from EPHEA, an organic alternative to leathers and synthetics, created exclusively for Balenciaga. The substance also utilizes minimal resources during production and emits minute amounts of CO2 as it feeds on low-value agro-industrial residue. Engineered to reduce an ecological footprint without compromising on quality or performance, EPHEA is the first of its kind to be cultivated on a pure mycelium basis, eliminating the need for contaminating chemicals during the growing process. The Balenciaga Maxi Hooded Wrap Coat made with EPHEA will be available in selected Balenciaga stores in Beijing, Beverly Hills, London, Milan, New York City, Paris, Shanghai, Tokyo and Toronto from the end of October.”

In our video interview with SQIM’s Co-Founder and Chief Mycelium Officer, Maurizio Montalti, that can be found above, he defines the Balenciaga EPHEA Coat as a true milestone and a testiment of their ability to produce new high quality, high performance materials from low value substances or by-products of other value chains at reasonable prices and extremely low environmental impact. “We work with nature for nature and as nature”, he states. Montalti is clearly proud to confirm that we are looking at at new category of materials altogether. “Its a material revolution”.

SQIM describes MOGU as “Green Building” & Interior Design/Architecture products and processes founded on Circular Economy principles. Industrial waste materials such as cotton and hemp fibres that cannot find other valuable applications in textile production are converted and valorised into « high performance products » – functional, beautiful and meaningful with a durable and sustainable life cycle as well as the lowest possible environmental impact.

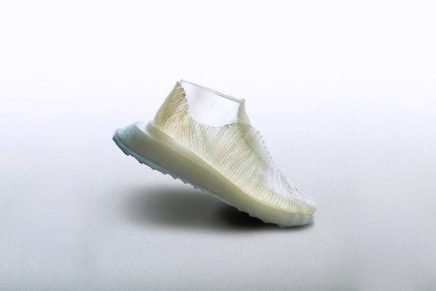

2. MODERNSYNTHESIS, “is a London-based biotech company bringing new materials to life. Merging biology with cutting edge textile processes, we are crafting an entirely new class of natural textiles that are circular by nature, and customisable by design,” they claim. (23) In essence, they are a “biomaterial start-up connecting the dots between biology, material science and design to craft progressive biomaterials for the fashion industry. The company’s ‘microbial weaving’ process employs bacteria to grow a strong, lightweight cellulose-based composite material that is naturally biodegradable and offers unique potential for customization”.

Their star product has been named the GANNI Bou Bag, a totally new natural fabric made from bacteria – a first-of-its-kind leather alternative. This clever material is one of the next-gen of responsible fabrics, powered by microbes to create a lower-impact textile, made with bacteria nanocellulose. It even feels as if it is from Bottega Veneta! “GANNI is on track to phase out all virgin leather by the end of this year, which has been a radical goal for us, » says Lauren Bartley, Sustainability & CSR Director, GANNI, the cult Danish fashion brand founded in 2000 by gallerist Frans Truelsen. “But the work doesn’t stop here. Working and trialing with partners like Modern Synthesis to develop more responsible and durable leather alternatives is crucial for us. Doing so enables us to create high-quality design products in lower-impact materials – changing the future of fabrics as we know them today. By partnering with Modern Synthesis to develop our iconic Bou Bag from bacteria, we get another step closer to our goal of having 10% of materials coming from our ‘Fabrics of The Future’ by 2025 – and we can’t wait to see what else we can make with Modern Synthesis’ technology.”

First shown at the Material Matters fair at London Design Festival 2023, “the handbag, made by cultivating nanocellulose – a fibre produced by certain bacteria – over a framework of threads, offered a vision of the future. “Working with bacteria has allowed us to tap into billions of years of evolutionary efficiency to push the boundaries of what natural materials are capable of,” ex-Adidas designer and co-founder of Modern Synthesis, Jen Keane told designboom.(24) The fascinating array of high-performance materials microbes already produce in nature enables us to rethink the way we build the products we use every day. Equipped with this deeper understanding of biology, we can bring life to a new class of materials designed for purpose from the nanoscale up,’. ‘We are excited to see the fashion industry now waking up to the commercial potential of lower-impact biotextiles as a compelling alternative to polluting animal and petroleum-based products.’

By presenting this one-of-a-kind piece, both Modern Synthesis and GANNI were holding a mirror up to the potential of design and provided a glimpse into the promising future of biomaterials within the commercial realm.

3. GOZEN (also see video interview above) is a biocreation startup founded by ex-fashion designer and now a material researcher and biodesigner, with a “mission is to reshape how we interact with the world around us, advocating for natural connection and a balance between creative expression and the sanctity of our planet. Gozen’s timeless process combines the ancient practices of harnessing naturally occurring processes with cutting-edge technology. This transforms organic elements into applied innovation – like her debut material, LUNAFORM™. Her research it aims to make sustainable production models and nature friendly biomaterials available for use in every field, not only fashion. “I work on bio-leather and bioplastic. Bio-leather is a material produced without killing any animals; it’s not processed in a way that would harm the environment and it’s 100% biodegradable.” (25)

Unveiled by Balenciaga for its S/S 24 collection at Paris Fashion Week, the ‘Balenciaga Lunaform Coat’ was anointed as “Best Luxury Product of 2023” at the Animal-Activist PETA Annual Awards. “It was the first time the material had been applied in fashion. It was specifically designed for Balenciaga. The animal and plastic-free textile LUNAFORM™ is grown from fermented nanocellulose and is a first-of-its-kind sustainable material. The process of creating LUNAFORM™ combines nature’s ingenuity with cutting-edge science. In a nutrient-rich environment, microorganisms craft ultra-crystalline patterns, and with the introduction of natural agents, a 3D super-material begins to form. From this entirely bio-based foundation, LUNAFORM™ is derived. The entire process is vegan and non-GMO, and the material, rather than being composed of microorganisms, is the by-product of their innate activity”. It is thinner and stronger than animal leather and can be thickened in a single layer to match the thickness of an animal leather. (26)

There are numerous other interesting new bio-innovators, for too many to list here, that are certainly worth mentioning, such as Insempra, Curie Co, Romilly Wilde and the entire BIOFAB community.

Are there Downsides to Bio-fabrics?

While the biofabrics themselves do not directly use pesticides or arable land and are water efficient in their production compared to conventional fibres, many of course make use of crops, such as sugar, that may have been grown and processed using chemical inputs and obviously require land and water to grow. (27) Some also use energy intensive processes. For example, Ecovative, initially used a drying process that was extremely energy intensive, though they have since found a drying method that is much more efficient.

At the moment, as the majority of these new fabrics are still in the development stage (though many are working towards scalability within the next 1-2 years) there is limited data available and no full life cycle assessments to draw upon, leaving many questions unanswered. For example, how durable are they? For biofabrics touted as a more sustainable alternative to leather – a material known for its longevity and ability to develop aesthetically with age – this is especially important. There is not publicly available data at the time of writing on the longevity and durability of these new leathers so it is a question that currently remains unanswered.

End of life is another area that is still unclear. Most are marketed as being biodegradable but whether you can add them to your garden compost heap or whether they require industrial composting is unclear. We’re certainly not at a stage yet where local authorities are offering biodegradable material collections at scale, though of course this could change in time. And whether these materials can be developed into a fully circular closed-loop system remains to be seen.

Then there is the IP (Intellectual Property) issue. You may have already noticed, and will notice even more, the extent to which these Biofab companies have patented and trade marked everything, just as pharmaceutical companies do, and for good reason. They clearly want to recover their investments and generate high profits from their innovations however, unless they are prepared to share their know-how freely as Tesla did, they will not help to save the planet quickly enough. What will become of the patents owned by Bolt Threads?

Besides the environmental impact, there is the social side to consider. With one in eight of the world’s adult population working in the fashion industry, from growing crops to sewing garments and retail, that is a huge number of jobs that would be impacted if biofabrics were to become the norm. And lastly, as Carole Collet, Professor in Design for Sustainable Futures at London’s Central Saint Martins college notes: “But even if we succeed in shifting from conventional linear manufacturing systems to more sustainable circular bio-based production models, we are still at risk of endorsing further our current overconsumption mindset. The bioeconomy can only succeed if we alter our consumption behaviors, and fundamentally rethink the notion of progress to create a new bio-modernity that is inclusive, interconnected, and mindful.” (28)

Spiber Eileen Fisher and Kering panel at the BIOFABRICATE Paris Summit 2024. Copyright: @BIOFABRICATE™. Photo Credit: Robert Leslie

Can Bio-Fabrics become the New Luxury Nobility?

We cannot say who decides what is noble and what is not. Would it be Hermès or King Charles III? What makes a material noble and for how long will they remain noble? Can luxury brands (excluding service brands) even exist without noble materials? Can a material earn its nobility or should it be ‘born’ noble? The term noble material is freely used in the luxury industry normally to imply that the material is derived directly from nature. In the case of animal skins, it would be assumed that the animal died for a noble cause – a handbag, a belt, a pair of shoes, eyewear? Having said that, we rarely if ever hear the expression used for a steak.

Is the term “Noble Materials” simply a marketing or sales argument against industrially-produced materials / ingredients? Perfumer and Author, Victoria Belim goes to great length to explain the importance of the term “matières nobles” in French perfumery as being natural essences that are difficult to produce such as absolutes (derived from vegetable matter – seeds, flowers, bark, wood or roots. She gives examples of Jasmin, Iris, Mimosa and wild Sandalwood but also includes Javanol from Givaudan – a rare sandlewood synthetic. Many perfume brands however tend to make noble material claims just to increase the price and may use only minute amounts if any”, she adds.

A relatively new niche ‘vegan’ perfume brand, Les Infinis from “Geparlys, Paris” created by investors and exporters (not perfumers) has gone as far as naming a perfume, “Matières Noble”, with a smiling declaration that it contains “Deliberate overdose of prohibited fruits”.

Are they using the words ’noble materials’ simply a marketing added value term?

Beneath luxury creation and craftsmanship stories we will always find mentions or rare or ‘noble’ materials. Whether we are speaking of fine fragrance, leather goods, timepieces, hotels or automobiles, we will find such ‘ingredient’ stories embedded in the quality claim.

The ‘old nobility’such as Hermès, may be quick to decline such a term for such lab-born natural materials. As we no longer have kings to decide what is noble or not, would the final decision need to be made by the established noble houses?

Here are some examples of how Hermès currently uses the term, (29) “Hermès uses, respects and preserves the most noble materials, secures its supplies and seeks to limit their impact on biodiversity”. ….” only the most noble materials are used. They bring the promise of long life to each object. Hermès monitors its supply chain very closely, chooses renewable materials carefully from responsible industries and manages their environmental impact, in particular on biodiversity”…” breathing new life into noble natural materials through a multitude of initiatives” …or for their new lipstick line, Rouge Hermès, “the choice of noble materials such as metal and the refillability of the lipsticks are evidence of a design that cultivates a sense of detail as well as an environmental commitment”. They seem to have narrowed their use of the term for fine natural materials that are also ‘clean’/sustainable.

Let us not forget that it was the Industrial Revolution that gave birth to innovative ‘material stories’ and that it was quite understood that these industrial materials would not be defined as ‘noble’ materials, not only due to the industrial and chemical processes used to obtain such materials but also, perhaps, due to the imitation objectives of those materials. Bio-fabrics cannot be accused of the same. They do not aim to imitate or to make a cheaper version of an animal leather and the like. They are true creations from nature, unique materials created from nature almost as if they were created at the same time as all other organic materials on our planet. As such, the bio-engineers of today, are playing a godly role in a very real sense and their cause is indeed noble.

Surely Bio-Fabrics made directly from bacteria should be considered noble due to the fact that they are born directly out of natural components (albeit from man-manipulated processes). The bacteria did not ‘die for a noble cause’, on the contrary, it grew into it and brought noble materials to life, materials that are durable, look good and feel good! Surely they should be, by their very nature, considered as noble. Nobility is something that one is born with or that one has earned. Bacteria would not be considered as noble from birth but is seen to transforms itself into a noble material, noble enough to meet the stringent demands of the most prestigious luxury maisons.

Perhaps such complex new innovative materials should simply be referred to as ‘knowble materials’ for those who are in the know and can appreciate, until the time comes when the classical luxury industry feels ready to bestow the highest quality ‘biofabs’ with the respectful description of noble that will by then have been well earned.

Still in its infancy, the field of bio-engineering seems to offer the most planet-friendly and noble alternative materials of a quality high enough to serve the luxury industry. Luxury houses are constantly in search of meaningful, ethical and sustainable solutions to petrochemically-derived materials that may end up in wastefills but they cannot be seen to compromise their quality offers. The development of an improved, ecologically sustainable production chain for high quality alternative fibres in parallel with an integrated quality system for raw and processed fibres based on eco-labelling criteria could contribute to the further development of a competitive, innovative and sustainable bio-based textile fibre industry. (30)

Bio-based alternatives seem to be offering the prospect of a real way forward. Biofab-based solutions are indeed being embraced by the luxury sector, in instances where high quality and very attractive materials have been successfully produced. Is it not time for them to finally be termed, ‘noble materials’?

References:

- AUSLANDER,L. “Taste and power : furnishing modern France”(1996). Berkeley : University of California Press p58.

- Maxine Berg, “In Pursuit of Luxury: Global History and British Consumer Goods in the Eighteenth Century” (2004) Past & Present, Vol 182, Issue 1, Feb 2004, pp 85–142

- Schiros,T,N, Mosher,C,Z, Zhu,Y, Bina,T, Gomez,V, Lee,C,L, Lu,H,H, Obermeyer, A,C, “Bioengineering textiles across scales for a sustainable circular economy”in Chem 7, 2913–2926, November 11, 2021 a 2021 Elsevier Inc.

- Deckers,J, Manshoven,S, and Mortensen, L, F, “The role of bio-based textile fibres in a circular and sustainable textiles system” ETC-EEA Technical Report Feb 2023

- Nomoto,S, “The Boom in Vegan Fashion” https://www.sandranomoto.com/2021/10/12/the-boom-in-vegan-fashion/

- https://www.harpersbazaar.com/uk/fashion/fashion-news/a30640996/vegan-leather-sustainability/

- Feldner-Busztin, E, “Between aspiration and action: the viability of creating new sustainable materials” in The-Interline-Sustainability-Report-2023 p23-28

- https://www.un.org/en/chronicle/article/dry-tears-aral#:~:text=The%20world’s%20fourth%20largest%20lake,less%20than%2040%20years%20ago.

- https://www.maisonbonnet.com/en/materials

- Animal-welfare-policy-november-2023-edition-23112023-publication-part_def.pdficy-november

- Patti, A and Cicala, G,”Eco-Sustainability of the Textile Production: Waste Recovery and Current Recycling in the Composites World” in Polymers 2021, 13(1), 134

- Tagle, C,D, “Where and why fabric waste originates“ in The-Interline-Sustainability-Report-2023 p17

- https://lesmateriauxparisiens.fr/

- https://www.commonobjective.co/article/what-are-biofabrics-and-how-sustainable-are-they

- Feldner-Busztin, E, i.b.i.d

- https://www.voguebusiness.com/sustainability/balenciaga-releases-coat-made-with-ephea-a-leather-alternative

- Feldner-Busztin, E, i.b.i.d

- Feldner-Busztin, E, i.b.i.d

- https://www.sqim.bio/1497-2/

- https://www.balenciaga.com/fr-fr/winter-22

- https://www.voguebusiness.com/sustainability/stella-mccartney-backed-leather-alternative-mylo-halts-production-bolt-threads-kering-ganni-adidas-lululemon

- https://hypebae.com/2022/10/balenciaga-ephea-coat-mushroom-leather-plant-based-alternative-images-info

- https://www.modernsynthesis.com/

- https://www.designboom.com/design/modern-synthesis-ganni-bou-bag-leather-alternative-bacteria-textile-ldf-09-20-2023/

- Schiros,T,N, Mosher,C,Z, Zhu,Y, Bina,T, Gomez,V, Lee,C,L, Lu,H,H, Obermeyer, A,C, “Bioengineering textiles across scales for a sustainable circular economy”in Chem 7, 2913-2926, November 11, 2021 a 2021 Elsevier Inc p2923

- https://www.prnewswire.com/news-releases/lunaform-a-new-kind-of-biomaterial-unveiled-by-balenciaga-at-paris-fashion-week-301947363.html

- https://www.commonobjective.co/article/7-biofabric-producers-you-need-to-know-about

- https://www.commonobjective.co/article/what-are-biofabrics-and-how-sustainable-are-they

- Hermès Animal Welfare Policy (November 2023 version) and https://finance.hermes.com/en/eco-design/

- Deckers,J, Manshoven,S, and Mortensen, L, F, i.b.i.d p30