The Journey of an All-Electric Marine Drive System in Pursuit of 50 Knots and Virtual Silence.

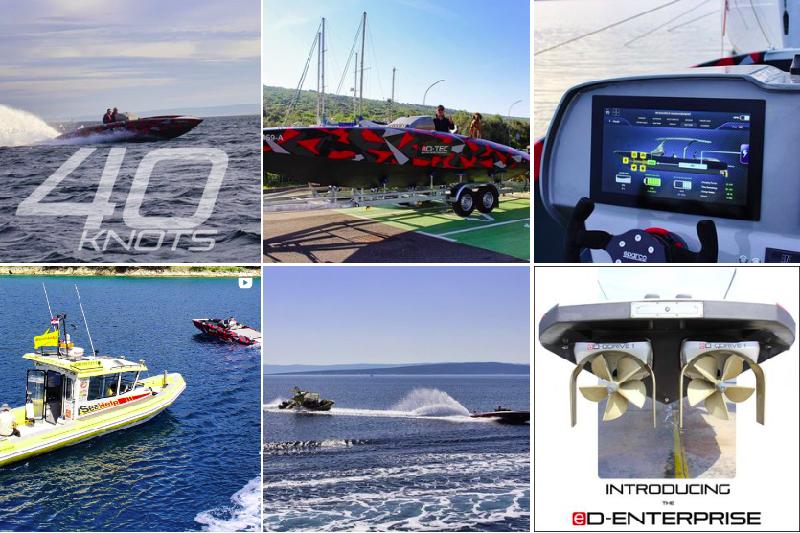

ED-TEC’s All-Electric ED-QDrive 1 Tops 40 Knots in Croatia in Second Phase of Testing.

Creating a pioneering, all-electric marine drive solution takes a lot of belief, technical knowledge and complex innovation – and the route to success is always strewn with challenges that need to be overcome.

In the pursuit of pioneering advancements in the maritime industry, the team at eD-TEC, along with their partner companies, has embarked on a groundbreaking journey to develop an all-electric marine drive solution. This ambitious endeavor has required unwavering belief, technical expertise, and complex innovations to overcome numerous challenges along the way.

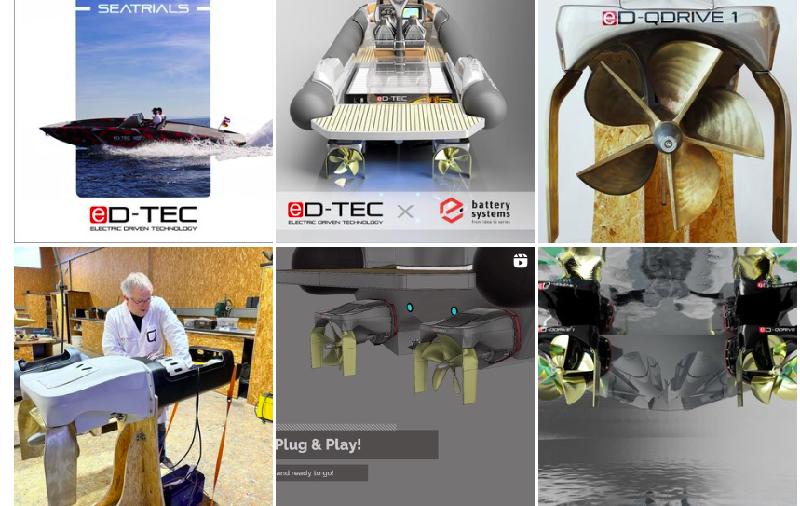

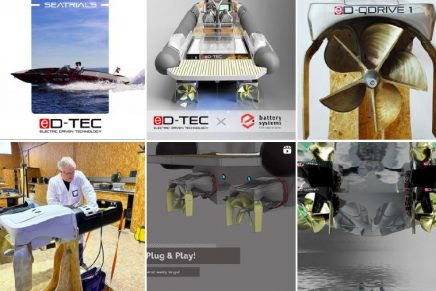

Being the first to venture into uncharted territory comes with its fair share of obstacles. For the Believer Team at eD-TEC, these challenges have revolved around high C-rate battery power, a sophisticated Technology Stack, plug-and-play sterndrive units, and high-torque motors previously unseen in the marine sector.

Following the initial phase of static and low-speed in-water testing conducted in April and early May, it was time to push the boundaries further. Thus, the eD-TEC Believer Team relocated their test monohull from Lake Constance to Marina Punat in Krk, Croatia, for a three-week period spanning from May to the start of June. The objective of this second phase of trials was clear: to assess the performance of the eD-QDrive 1 and its platform in the open sea without speed limitations, test the durability of system components, and unlock the full potential of this revolutionary propulsion solution.

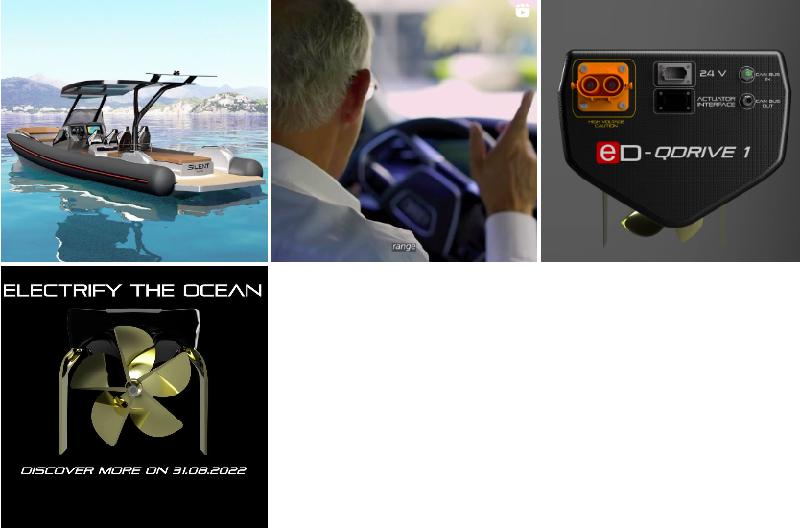

“We tested the entire system, from the plug-and-play drive units to the batteries. We’ve been extracting more and more power from the batteries while ensuring their longevity and health,” explains Marc Jost, Chief Strategy Officer at eD-TEC. “We optimized our software that controls the system and the Technology Stack, and conducted endurance testing. In total, we covered approximately 190 nautical miles.”

The testing process comprised several stages, beginning with a week of low-speed trials to familiarize the team with the system and allow for proper bedding-in. Jost elaborates, “We conducted multiple runs at around six to 10 knots and gradually increased the speed in 500rpm intervals, starting from 500rpm. Each stage of testing was conducted over an extended period to ensure the optimal performance of all systems. After a week of testing, we observed that the system was completely stable and reliable, prompting us to progress to higher speeds, starting at 25 knots.”

During the trials, the team achieved a remarkable top speed of 40 knots while operating the motors well below their maximum power capacity, indicating significant headroom for even greater speeds. “Our goal is to reach 50 knots with the monohull, and we haven’t fully utilized the capacity of the batteries and motors yet,” affirms Jost. “During this phase, we were still fine-tuning the software, so we erred on the side of caution to avoid any component damage. Nevertheless, we are quite satisfied with achieving 40 knots at lower power levels.”

The first phase of testing revealed some technical challenges, such as electrical noise caused by high-torque motors, which is expected when venturing into unexplored territory in electromobility technologies. However, the tests conducted in Croatia not only demonstrated the effectiveness of the solutions developed by eD-TEC and their partner companies, but also showcased the system’s significant potential beyond the initial design parameters.

Jost explains, “We encountered no issues with the electrical components during the tests; everything ran smoothly. Furthermore, we engaged in discussions with the motor manufacturer, and we will receive an upgrade that will simplify the system and mitigate electromagnetic noise.”

Overall, apart from one instance requiring a return to Germany to resolve a gearbox problem, the performance of all systems delighted the team. Jost adds, “We were pleasantly surprised by the lower-than-expected temperatures observed in the motors, batteries, and cooling system. It indicates that we have implemented an adequate cooling system – or perhaps even slightly overengineered it. But that was a welcome surprise.”

Throughout the testing period, the team extensively charged the system using a 22 kW power supply from the marina, fully charging the batteries in approximately three hours. Marina Punat provided invaluable support, assisting with the lifting of the test boat in and out of the water, and offering berthing facilities and other forms of assistance.

“Marina Punat has a vision and a strategic plan to become self-sufficient and green in terms of power by 2030,” explains Jost. “We also received assistance from SeaHelp, which is akin to roadside assistance for boats. They provided a patrol boat to accompany the sea trials and ensure safety. Both these companies exemplify the type of partners and local Believers that eD-TEC attracts.”

With the completion of the second phase of trials, the testing process now progresses to its third and final phase, wherein the eD-QDrive 1 system and Technology Stack will be installed on a purpose-built Silent Speed 28 boat. The objective of this phase will be to achieve a new speed milestone.

“Our team eagerly awaits the installation of the ED-QDrive 1 on the Silent Speed 28,” concludes Jost. “We are confident that the final product will surpass expectations. It will be a fast, reliable, comfortable boat with a substantial range, operating in virtual silence. Moreover, thanks to the intuitive and ergonomic user interface, it will be enjoyable and effortless to use.”