Reconceived, redesigned and reworked: Urwerk UR-220 Falcon Project.

Although the UR-220 watch by independent watchmaker Urwerk has adopted some of the features of its predecessor, the entire movement has been reconceived, redesigned and reworked. The UR-220 is clad in carbon. This is the first time Urwerk has adopted the high-tech transformation of this common element. The result is an extremely tough but featherweight case, composed of 81 ultra-thin layers of high-resistance 150g CTP carbon compressed into a hard resin. The carbon structure of the UR-220 has a pattern all of its own with a finesse and regularity that emphasises the curve of the case.

“I wanted to have the finest possible pattern traced along the length of the UR-220’s case,” explains Martin Frei, URWERK’s other co-founder. “We, therefore, needed a special kind of carbon in layers that are not only parallel but as thin as possible. The concentric pattern you can see on the surface of the UR-220 is the result of this choice. The carbon layers underscore the curves of the sapphire-crystal glass of this watch. In terms of style and technique, this UR-220 is just the way I wanted it.”

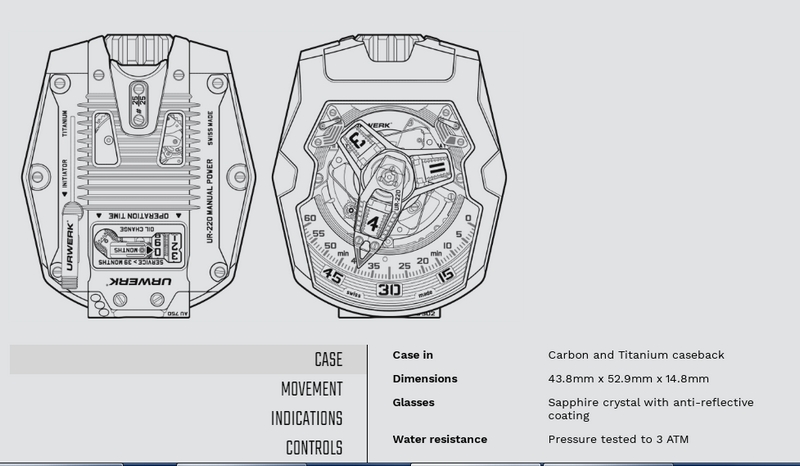

The back of the UR-220 Falcon Project watch shows how much the 200 series modules have evolved.

URWERK’s signature Oil Change indicator returns after years of absence to show the accumulated engine running time of the watch. This

original type of information had for long featured in the UR-110 models. It returns with some well thought out upgrades.

In the UR-220, the Oil Change indicator takes the shape of a numerical counter calibrated in months, shown on two adjacent rollers. The log of the movement’s running time is started by the owner of the watch who removes a security pin and presses the pusher on the back of the UR-220.

From then on, the counter displays the accumulated running time of the watch in months. When it reaches 39 months, it is time to take the watch in for a service and oil change. URWERK’s watchmakers will set the counter back to zero and replace the pin at the end of the service. “It’s more than a numerical counter making a cold tally of the months,” says Felix Baumgartner, URWERK’s co-founder. “The Oil Change indicator tells you for how long your watch has actually been working on your wrist, and reflects the energy you have fuelled it with every day. It connects you with your watch.”

The UR-220 adopts the patented satellite indication of its predecessor, in which the wandering hours are indicated on three rotating cubes.

In turn they pick up the minutes pointer as they enter the 120° scale of 60 minutes. At the end of the hour, the minutes pointer leaps back to the start of the scale to be picked up by the next hour. To minimise the inertia of the retrograde minutes, each side of the pointer has been pierced to make it as light as possible.

The only other indication on the dial is that of the power reserve. This is displayed on two up/down gauges, each of 24 hours. When the

movement is wound, the right-hand gauge reacts first. As soon as it shows 24 hours of power reserve, the left hand gauge takes over. Splitting the power reserve indication turned out to be a complex task, requiring 83 mechanical parts.

With the UR-220’s strap, Urwerk again ventures into new territory.

It is the company’s first rubber strap, and therefore has to be something special. The strap is cured, molded and textured by the Vulcarboné process which gives it a touch like velvet. Many years of research into nano-textures were needed to create this effect. Then the strap is stitched and finished by hand to ensure supreme comfort, strength and appearance.