Designed by the renowned Carlo Colombo, the Bentley Newent creations are the latest additions to the Bentley Home collection. Each piece of furniture is individually finished by hand.

The curves of the Newent designs, echo those of the Richmond Collection, the first Bentley Home line, launched in 2013. This distinguished previous collection has provided a source of inspiration for the Newent line, and allowed the design structure to progress to softer shapes.

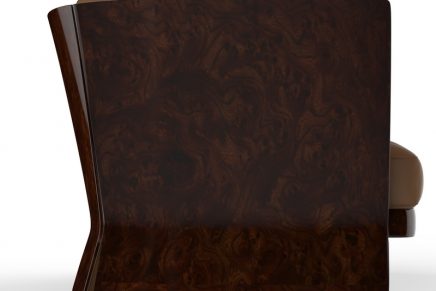

The Newent sofa is the star of the collection, with a stunning armchair, chair and bed available to match. The pieces can be either fully upholstered in the customer’s choice of leather or fabric, or with a veneered frame. Available in the most iconic walnut briarwood design, the frame envelops the curved profile of the sofa, highlighting and enhancing the differing angles that characterise its elegant, tapered shape.

The human touch guarantees that each piece is unique.

To achieve the standards required to finish a piece of Bentley Home furniture, a human touch is vital. Veneering, for example, is hand-inlaid and positioned with a hot-vacuum membrane press. The bending moulds, requiring the handiwork of highly-skilled craftspeople, are made specifically for Newent designs. This procedure is extremely precise and is completed by hand. The special double curve visible in the lower side of the frame does not show any divisions or joints between the parts curved in different directions. This result comes via the manufacturing technique of thermoforming, which uses innovative processes and materials.

“We work very closely with our colleagues at Bentley Home to ensure the furniture we create embodies the exacting standard in design and manufacture we have in our cars,” commented Chris Cooke, Bentley’s Head of Product Design.

“From the language and flow of the surfaces to the detailed execution of the veneering process, the ‘Newent’ range is a great example of what we do best, create luxury products for discerning customers.”

Both Bentley Home and Bentley Motors use high-frequency machine presses for curved pieces; sharing the use of a very advanced technology that can create these smooth and rounded shapes that have become so iconic. The flat press machine, for bonding the veneers to the support, is also used by both Bentley Home and Bentley Motors. Both partner brands also follow the same process for veneer preservation, storing woods in rooms with a constant temperature to avoid changes in the wood patterns that can occur from exposure to other elements, or transitions from dry to damp.

Made for the Discerning Eye

The new furniture range can be customised in the finishes that have made the British brand unique, from the most exquisite leathers and wood veneers.

Pieces are available either fully upholstered in leather or fabric, or with the frame veneered. The options echo Bentley’s automotive codes and include Burr Walnut or Smoked Liquidambar.

One bundle of veneer woods is used per small furniture piece (such as a chair or armchair) ensuring a consistent finish. Similarly, one bundle of veneers is used per Bentley car. For larger pieces of furniture, such as a bed or single piece sofa, a larger number of veneer leaves is needed, and therefore multiple bundles are used. This requires craftspeople to select the most similar-looking briar-root patterns and grains from different bundles for a uniform result: close attention to detail is required again.