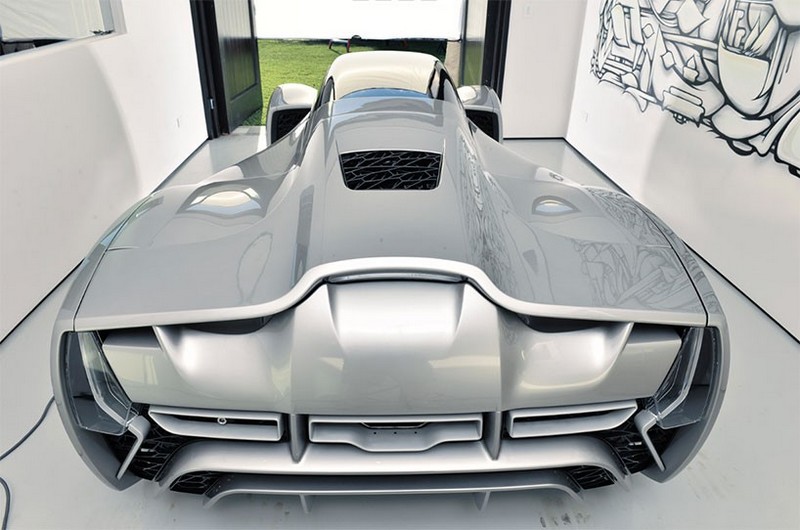

Building the perfect beast.

Finally, a sustainable manufacturing platform.

3D printing in the automotive industry design could open the gate to a new universe of car concepts and manufacturing methods.

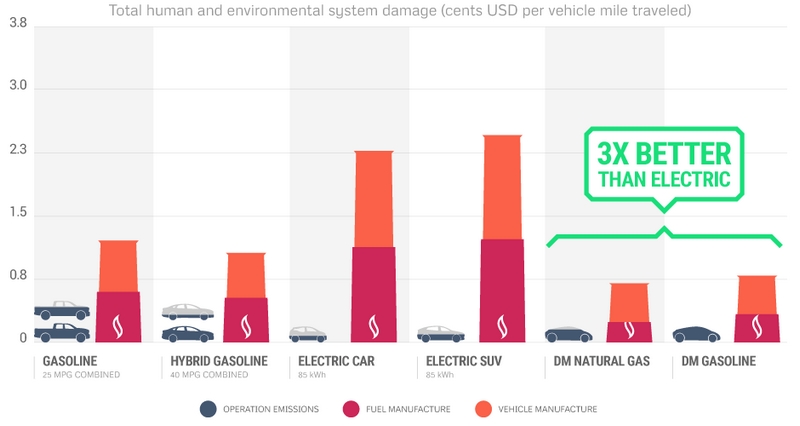

American start-up Divergent Microfactories came with a disruptive new approach to auto manufacturing that incorporates 3D printed nodes connected by carbon fiber tubing that results in an industrial strength chassis that can be assembled in a matter of minutes. The new manufacturing method using 3D printing reduces the pollution, materials and capital costs associated with building cars.

“Society has made great strides in its awareness and adoption of cleaner and greener cars. The problem is that while these cars do now exist, the actual manufacturing of them is anything but environmentally friendly,” says Kevin Czinger, Founder & CEO, Divergent Microfactories.

‘We’ve found a way to make automobiles that holds the promise of radically reducing the resource use and pollution generated by manufacturing. it also holds the promise of making large-scale car manufacturing affordable for small teams of innovators. and as blade proves, we’ve done it without sacrificing style or substance. we’ve developed a sustainable path forward for the car industry that we believe will result in a renaissance in car manufacturing, with innovative, eco-friendly cars like blade being designed and built in microfactories around the world,’ added Czinger.

According to Czinger, using the technology, the automotive industry could build anything from a two- seat sports car to a pickup.

Czinger is absolutely convinced that the technology is strong enough to build safe cars. The team have tested the strength and durability of the chassis, and it is even stronger than current technology.

Divergent Microfactories could produce from a few cars up to 10,000 cars per year for production factories.

Blade goes from 0-60 in about 2 seconds. That’s faster than a McLaren P1 supercar. It also has 2x the power-to-weight ratio of a Bugatti Veyron. The car uses a 700 HP, 4-cylinder turbocharged internal combustion engine fueled by compressed natural gas or gasoline.